Sowing complexes of the N series

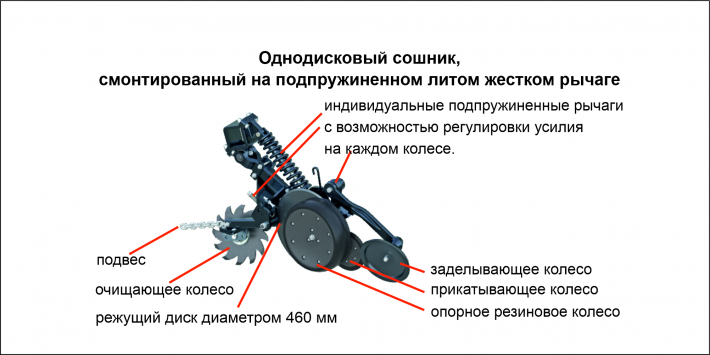

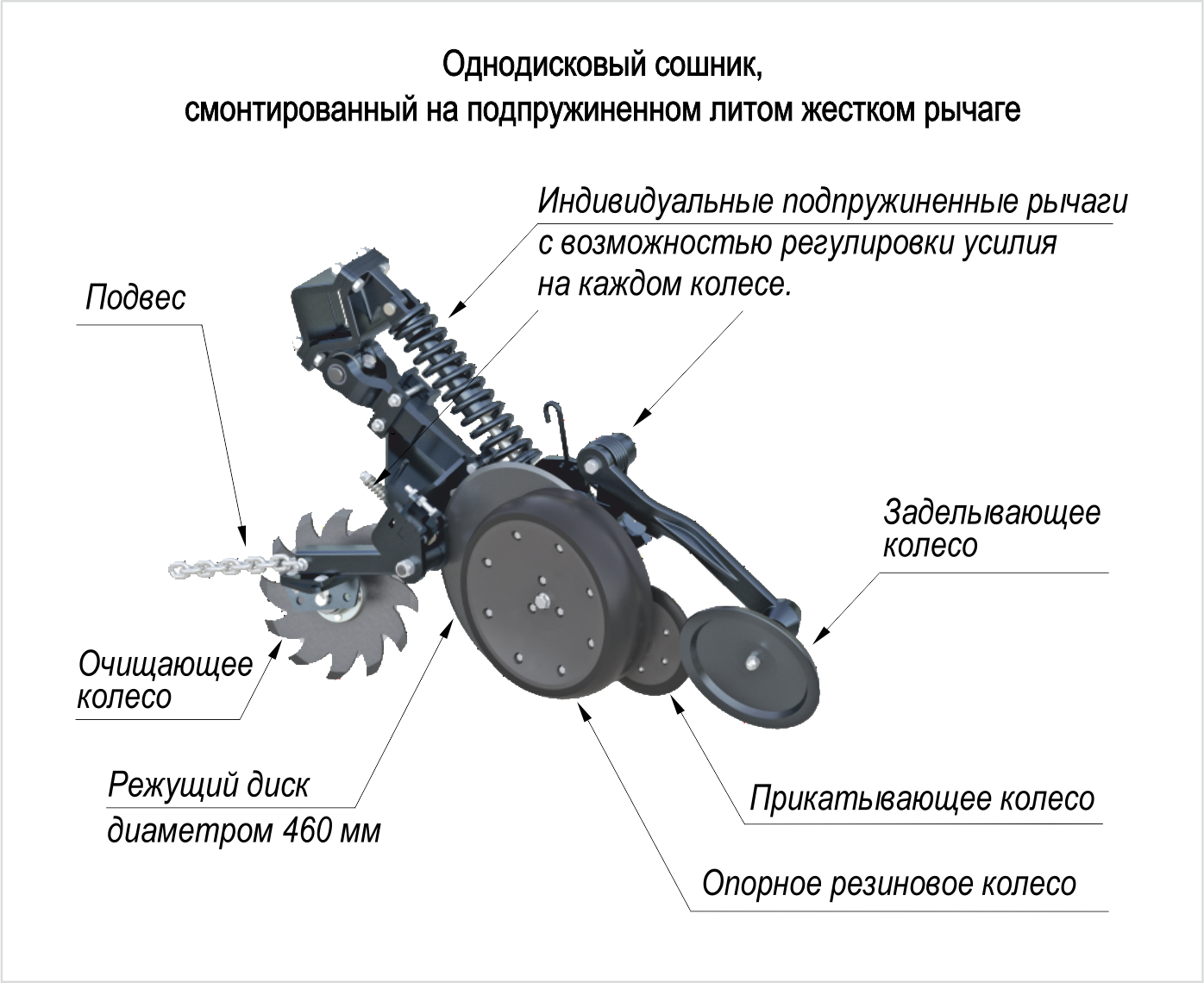

The sowing complex of N series is designed for sowing grains, legumes, oilseeds, as well as grasses using minimal (Mini-till) and zero (No-till) technologies with the simultaneous application of dry granulated fertilizers. A distinctive feature of this sowing complex is a single-disc coulter mounted on a spring-loaded cast rigid lever with a rubber support wheel, which allows you to develop a cutting force of up to 180 kg.

Sound PRO! arguments for the sowing complexes of N series:

FRAME OF THE SOWING COMPLEX

● Reinforced frame, rigid in all directions of application of the traction forces;

● The frame design adopts thick-walled profile pipes made of 09G2S steel, which is distinguished by excellent weldability and increased strength;

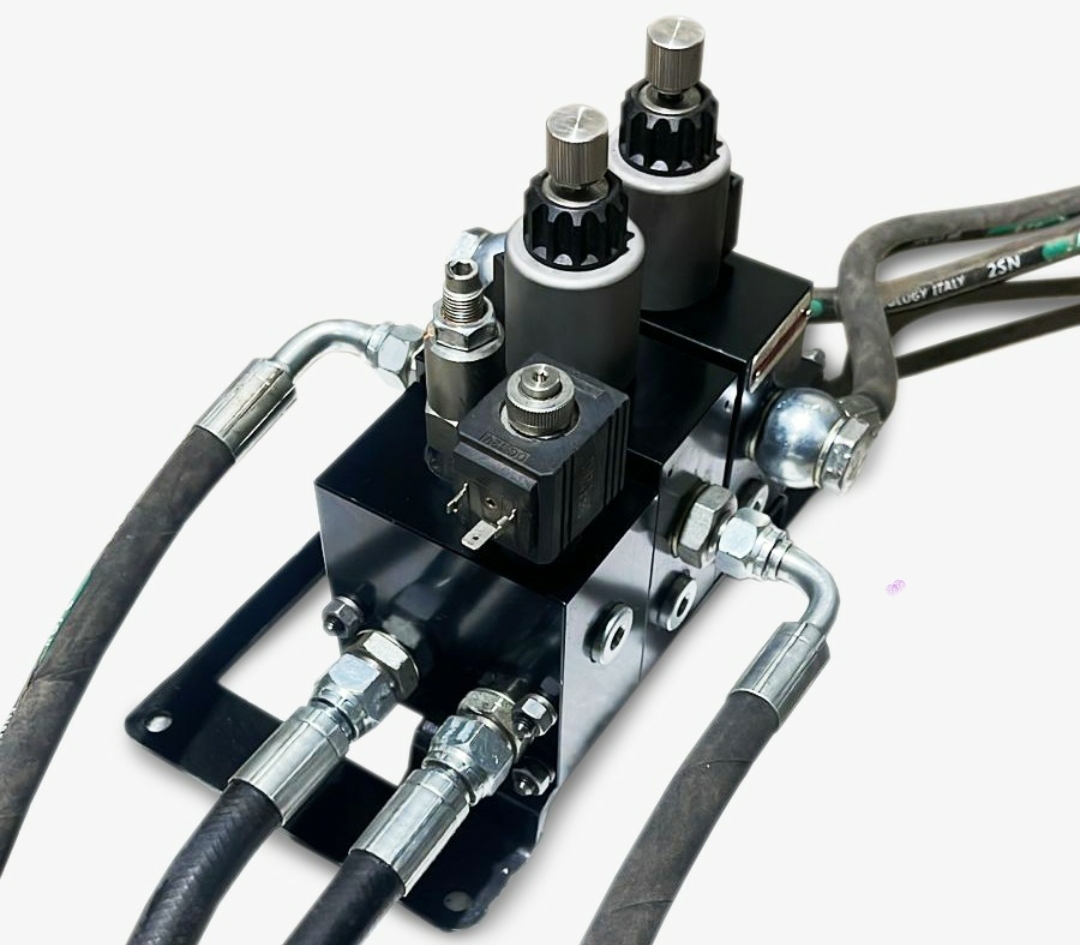

● The hydraulic system with a pressure control valve and hydraulic accumulators allows you to adjust the required clamping force of the working bodies and maintain it constantly during operation;

● When manufacturing the frame and working bodies of the complex, advanced exclusive technologies such as HD-surface hardening, electrospark alloying, etc. are used;

● There are easy-to-maintain seed distributors installed on the frame of the sowing complex, which distribute the seed material with high precision.

HOPPER OF THE SOWING COMPLEX

● The sowing complex can be equipped with a front-mounted hopper with a volume of 6.8 m3 (factory package) or with a volume of 10 m3 (option);

● The hopper is divided into two parts at a ratio of 40/60, which allows you to distribute the loading of seeds and dry granulated fertilizers;

● The sowing complexes of N series are optionally completed with liquid fertilizer application systems (KAS type) with a drive from the diaphragm piston pump;

● For operational safety purposes, there are ladders and enclosures installed on the seed hopper, as well as a special anti-skid coating on the surface of the hopper;

● In order to load the seed material quickly, there is a screw loader with LED lighting installed, which allows you to load in the dark and to operate the sowing complex in two shifts;

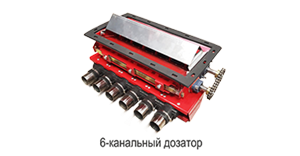

● The six-channel distribution of the seed flow provides the dosing accuracy in the whole coulter group and minimum damages to the seed materials;

● The application of modern composite materials and stainless steel in the dispenser design makes it reliable and durable even when working with mineral fertilizers;

● The kinematic scheme of the dispenser drive through the variator has a wide range of variation in the rotational speed of the dispensing coils, which allows setting of the seeding rates from 2.5 to 400 kg/ha.

● A set includes 2 types of seed wheel coils – standard coils for sowing of grain and legume crops; and small-seeded ones – for sowing small-seeded crops such as rapeseed, camelina, alfalfa and others;

● The variator shaft is equipped with a cutoff clutch to prevent breakage in case of clogging of the dispenser coils.

WORKING BODIES OF THE SOWING COMPLEX

● The working bodies (coulter discs, wheels) are made of high-tensile steels, using the advanced methods of thermal treatment and hardening;

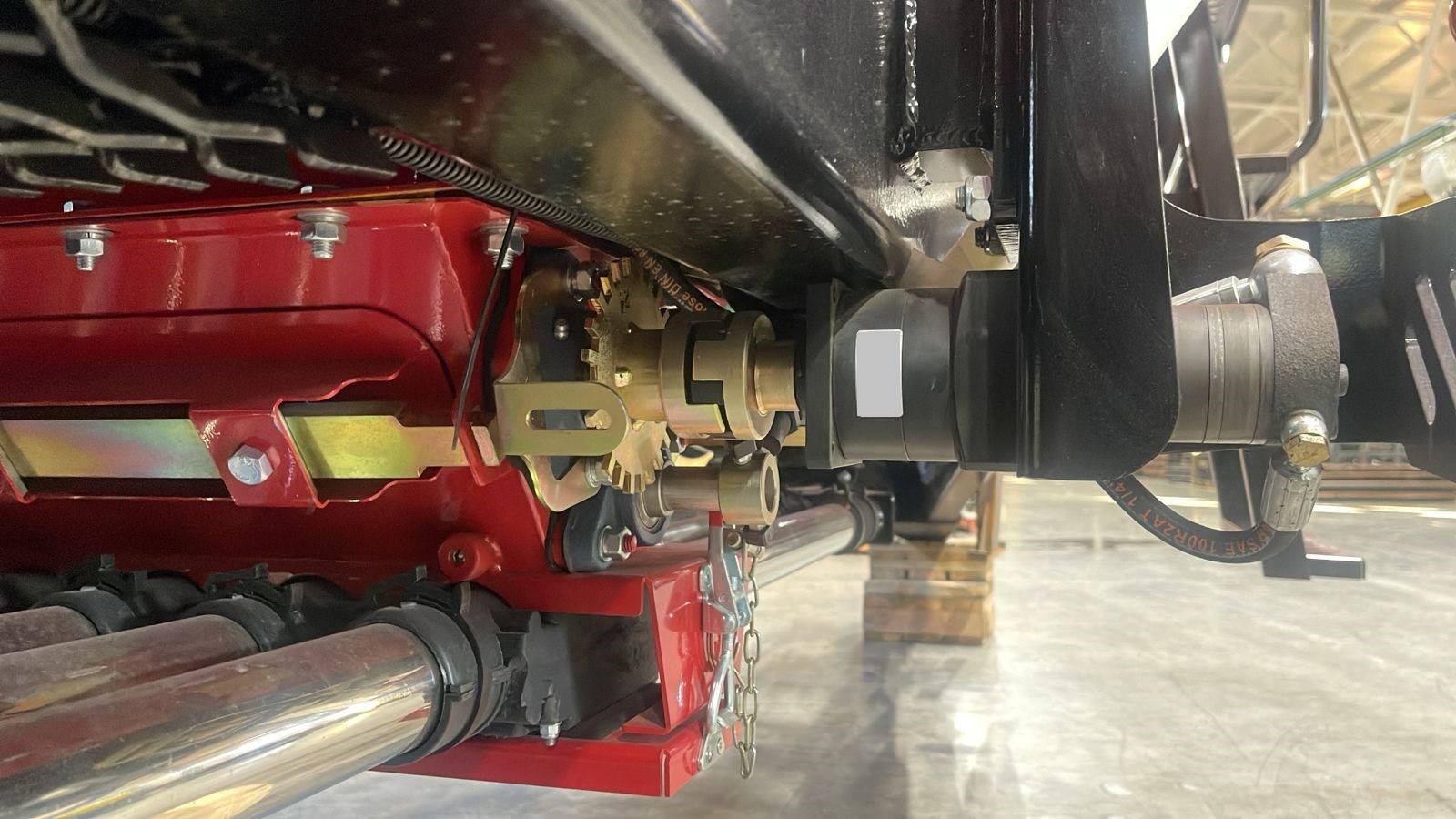

● The clearing wheel, located at an angle in the direction of travel with the ability to adjust the wheel position, allows you to clear the row of crop residues for high-quality cutting of soil of the disc coulter;

● Disc coulters (cutting discs) are mounted on a spring-loaded cast rigid lever with a rubber support wheel, which allows you to develop a cutting force of up to 180 kg;

● The seed spreader spreads the seed material at the bottom of the seedbed before the press wheel passes, which prevents the seeds from flying out of the furrow;

● The press wheel with adjustable pressing force creates the necessary density in the seed sowing area, thereby achieving perfect seed-to-soil contact;

● The covering wheel allows you to close the row after sowing and ensure the proper level of soil above the seeds;

● The sowing depth can be adjusted using a lock on the gauge wheel lever, which allows you to adjust the sowing depth in the range from 2 cm to 9 cm with a pitch of 1 cm;

● Disc coulters located in two rows and installed in a checkerboard pattern allow to exclude clogging of the unit with crop residues;

● The row spacing adjustment in the range from 190 mm to 250 mm allows the use of the sowing complex in different configurations;

● Thanks to the high ground clearance (300 mm from the cutting discs), an optimal comfortable transportation of the sowing unit is ensured.

● All assembly units of the complex, except for bearings, hydraulic cylinders and tires, are manufactured at our plant, which fact essentially simplifies the warranty and post-warranty maintenance of the machinery;

● To apply liquid fertilizers, the following devices are additionally installed on the sowing complex: a piping system, nozzles and feeders that are connected to the control unit installed on the hopper of the sowing complex.

SOWING CONTROL SYSTEM AND NAVIGATION OF THE SOWING COMPLEX

● The high maneuverability, transport speed and mobility make it possible to use the sowing complexes in remote fields of small dimensions, while reducing the energy consumption and increasing productivity in comparison with the traditional sowing technologies;

The sowing complex is equipped with a sowing control system, which includes:

- clutch starting unit, data collection unit;

- sensors of rotation of the dispenser shaft, fan;

- cultivator position sensor;

- hopper filling sensor, hopper pressure sensor;

- sensor of clogging of the seed tubes.

● The specified application rate of the seeds and fertilizers provides pressure in the hopper tanks. For operational monitoring of tightness in the hatches and good condition of other elements of the hopper, there is an excess pressure gauge installed in each tank. When the pressure in the hopper falls below the allowed value, a warning signal lights up on the monitor;

● The sowing electronic control system and the board navigation complex provide monitoring of the stable functioning of the sowing complex and parallel driving on the basis of GLONASS/GPS;

● There is an opportunity of easy reinstallation and use of GLONASS/GPS board navigation system.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Parameter name |

N-12000 |

|

|

Operating width, m |

12 |

|

|

Row width, mm |

19 or 25 |

|

|

Clamping force of the disc coulter, kg |

Up to 180 |

|

|

Cutting disc |

Ø460 mm, at an angle of 7 degrees |

|

|

Gauge wheel |

Ø410 mm, adjustable from 2 to 9 cm, with a pitch of 1 cm |

|

|

Press wheel |

Ø250 mm, with adjustable force from 2.5 to 20 kg |

|

|

Covering wheel |

Ø300 mm, with adjustable force from 12 to 20 kg |

|

|

Overall dimensions of the cultivator part in the transport position |

Length, m |

8,1 |

|

Width, m |

5,2 |

|

|

Height, m |

4,5 |

|

|

Road clearance |

300 mm on the cutting disc, 170 mm on the clearing row wheel (option) |

|