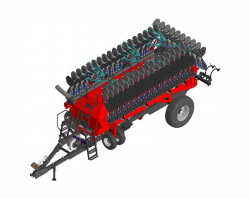

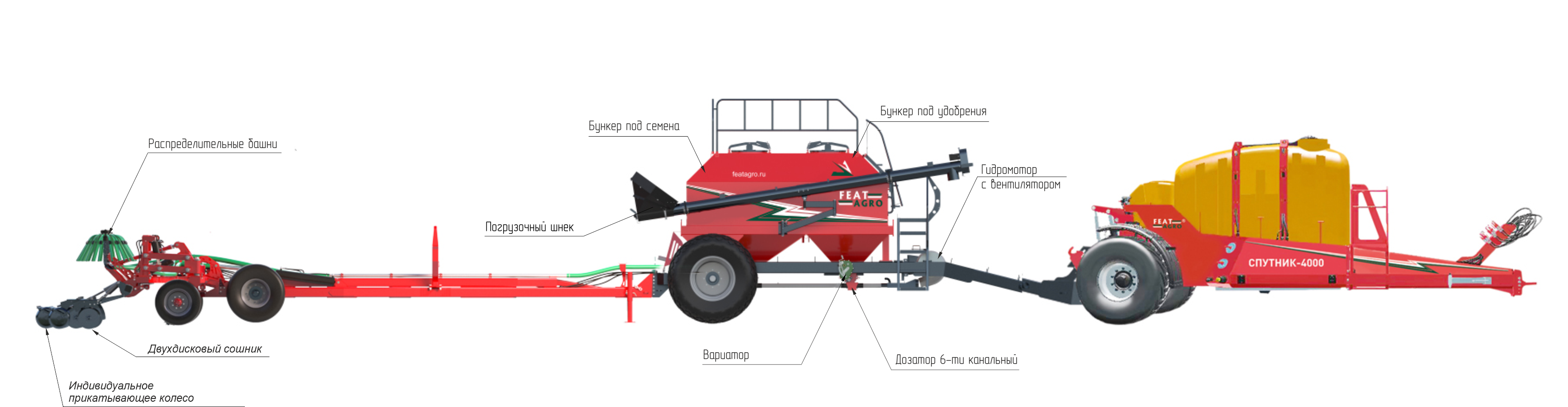

Sowing complexes of the S(3M) series

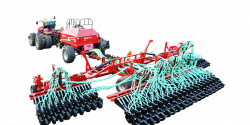

The S-series seeding complexes are unified under European transport standards, which solves the problem of transporting such large machines on public roads.

The seeding complex capture width is from 9.6 meters to 12 meters, which allows sowing up to 250 hectares per day and up to 5,000 hectares during the sowing period. The complex has a simple design and is reliable in operation.

If you use traditional soil cultivation technology in your farm, remember that the S-series seeding complex has all the necessary characteristics: precise and simple control of the seed placement depth, the ability to sow small-seeded crops, high productivity, work efficiency and, as a result, improved seedling quality and an increase in yield by 25-30%.

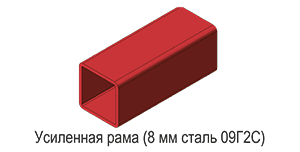

- Reinforced frame, rigid in all directions of traction;

- The frame design uses thick-walled profile pipes made of 09G2S steel, which is characterized by excellent weldability and increased strength;

- Rigid, but at the same time lightweight working part (frame with working bodies) allows to reduce the traction efforts of the tractor;

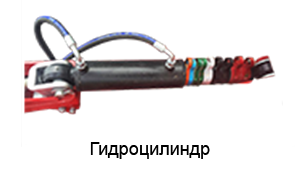

- The use of hydraulic cylinders of serial connection ensures a uniform level of deepening, simplifies technological adjustment and reduces the load on the frame and working bodies. This solution improves the quality of soil cultivation and increases the service life of the seeding complex;

- In the manufacture of the frame and working bodies of the complex, modern exclusive technologies are used, such as high-frequency current surface hardening, electric spark alloying, etc.;

- Easy-to-maintain seed distributors are installed on the frame of the seeding complex, which distribute the seed material with high accuracy.

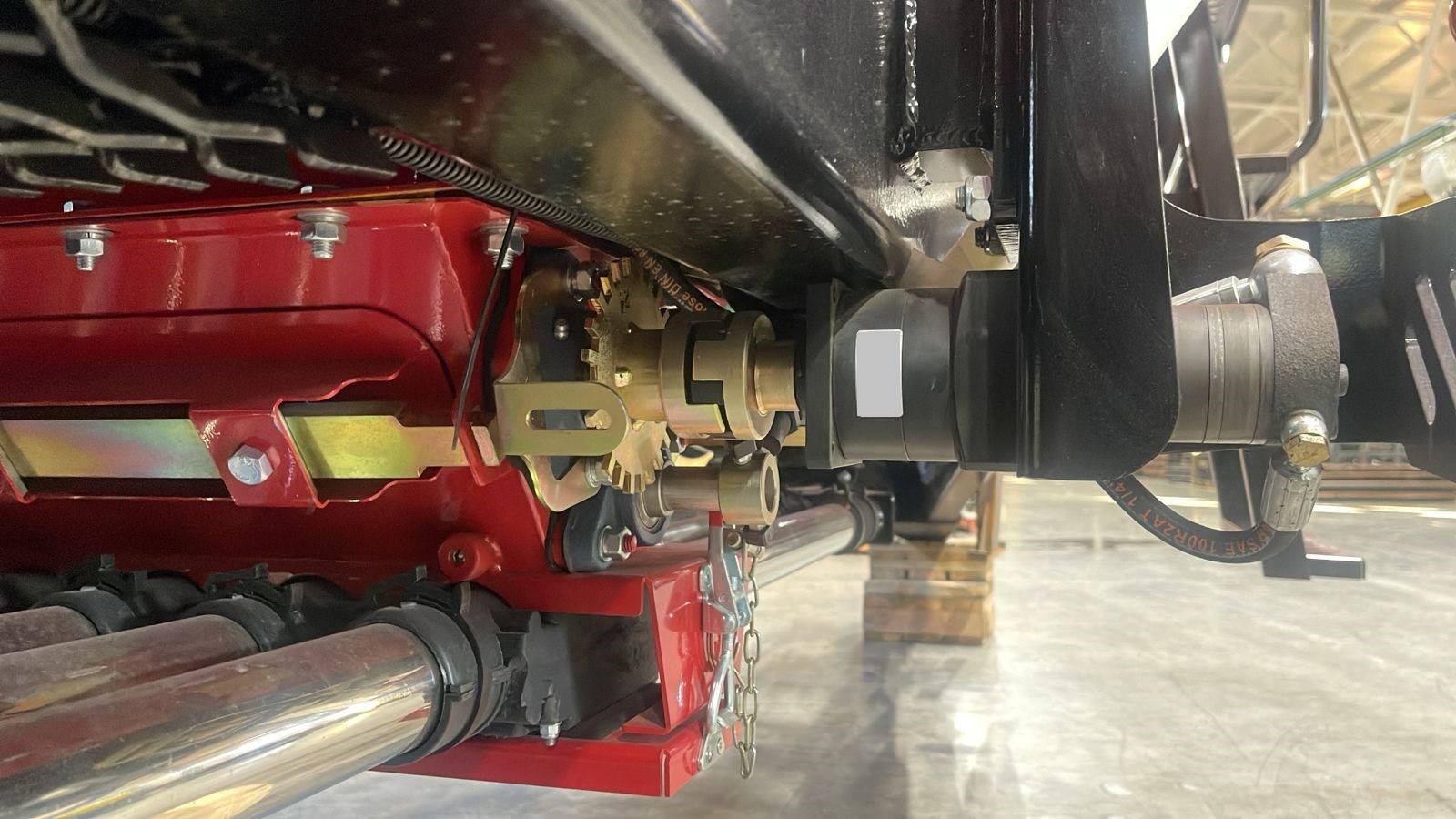

- Disc coulters with a guaranteed operating time on the bearing group of at least 200 hectares per coulter;

- The disc coulter mounting scheme allows for individual adjustment of the disc cutting force and the rolling of the seeded row, as well as of each disc block and all blocks simultaneously.

- Individual press wheels with FKL (Serbia) bearings that do not require maintenance serve as an ideal mechanism for closing the seedbed.

- The disc coulter group has not only individual mechanical spring adjustment, but also adjustment by hydraulic cylinders. With the help of these adjustments, it is possible to create pressure on the disc coulter of up to 82 kg, which allows working on different types of soil in different agroclimatic conditions, while maintaining a given seed sowing depth;

- Each disc coulter and press wheel have individual scrapers, which eliminates their clogging;

- The seed stacker (optional) distributes the seed material on the bottom of the seedbed before the press wheel passes, which eliminates the scattering of seeds from the furrow;

- Row-width cultivators (optional) remove traces from the passage of disc coulters, creating an even coating over the seeds;

- All units operating in extreme conditions are equipped with agricultural-grade bearings with a special triple seal FKL (Serbia)

- A dirt scraper (scraper) on the disc coulter casing prevents the disc coulter from clogging with soil and plant residues

- Semi-pneumatic rollers with an individual scraper - a guarantee of self-cleaning on high-moisture soil

- S-series seeding complexes are equipped with track cultivators, which are located on the seeder frame, this allows you to remove traces from tractor wheels and ensure uniform sowing with a disc coulter

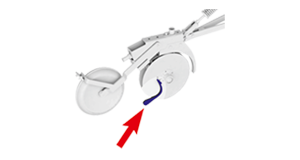

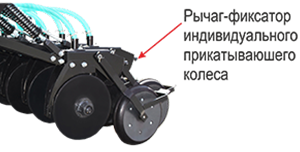

- The depth of seed placement is adjusted by moving the locking lever of the individual pressing wheel.

- The seeding complex bunker is a high-tech unit;

- One bunker location option is front, with a volume of 6 m3 (factory configuration);

- The bunker is divided into two parts in a percentage ratio of 40/60, which allows you to separate the loading of seeds and dry granular fertilizers;

- For operational safety, ladders and fences are installed on the seed bunker, as well as a special anti-slip coating on the surface of the bunker;

- For quick loading of seed material, an auger loader with LED lighting is installed, allowing loading in the dark, which allows you to operate the seeding complex in two shifts;

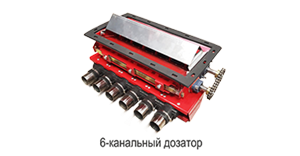

- Six-channel distribution of seed flow provides accurate dosing across the entire coulter group and minimal damage to the seed material;

- The design of the dispenser uses modern composite materials and stainless steel, which makes it reliable and durable, even when working with mineral fertilizers;

- The kinematic diagram of the dosing drive via a variator has a wide range of change in the rotation speed of the dosing rollers, which allows you to set seeding rates from 2.5 to 400 kg / ha.

- The kit includes 2 types of seeding rollers - standard for sowing grain and leguminous crops; and small-seeded - for sowing small-seeded crops such as rapeseed, camelina, alfalfa and others;

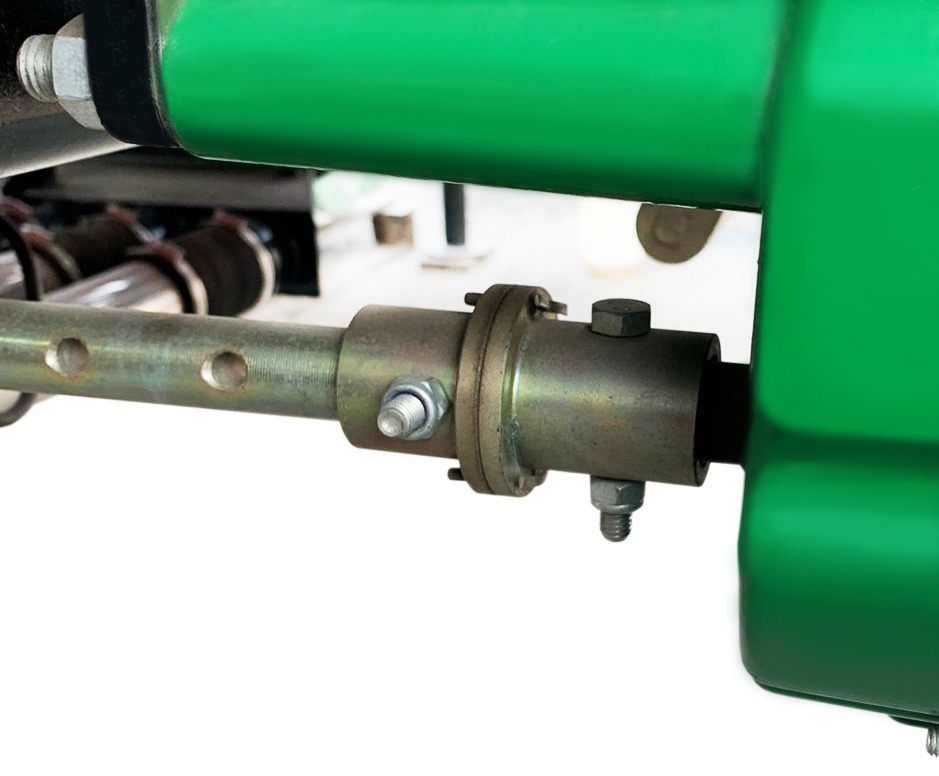

- The variator shaft is equipped with a breakaway clutch to prevent breakage in case of clogging of the dosing rollers

- The seeding complex is equipped with a SKIF seeding control system (Radian Plant), which includes:

- bunker sensors (clutch start unit, data collection unit, dosing shaft rotation sensors, fan, bunker filling sensor, bunker pressure sensor)

- sowing part sensors (seed pipe clogging sensor, cultivator position sensor). - The specified seed and fertilizer application rate is ensured by the pressure in the bunker tanks. For prompt monitoring of the tightness of the hatches and the serviceability of other bunker elements, an excess pressure control sensor is installed in each tank. When the pressure in the bunker drops below the permissible level, a warning signal lights up on the monitor;

- Electronic seeding control system and on-board navigation system - control of the stability of the seeding complex and parallel driving based on GLONASS/GPS;

- Possibility of easy reinstallation and use of the GLONASS/GPS on-board navigation system on sprayers and other agricultural machinery.

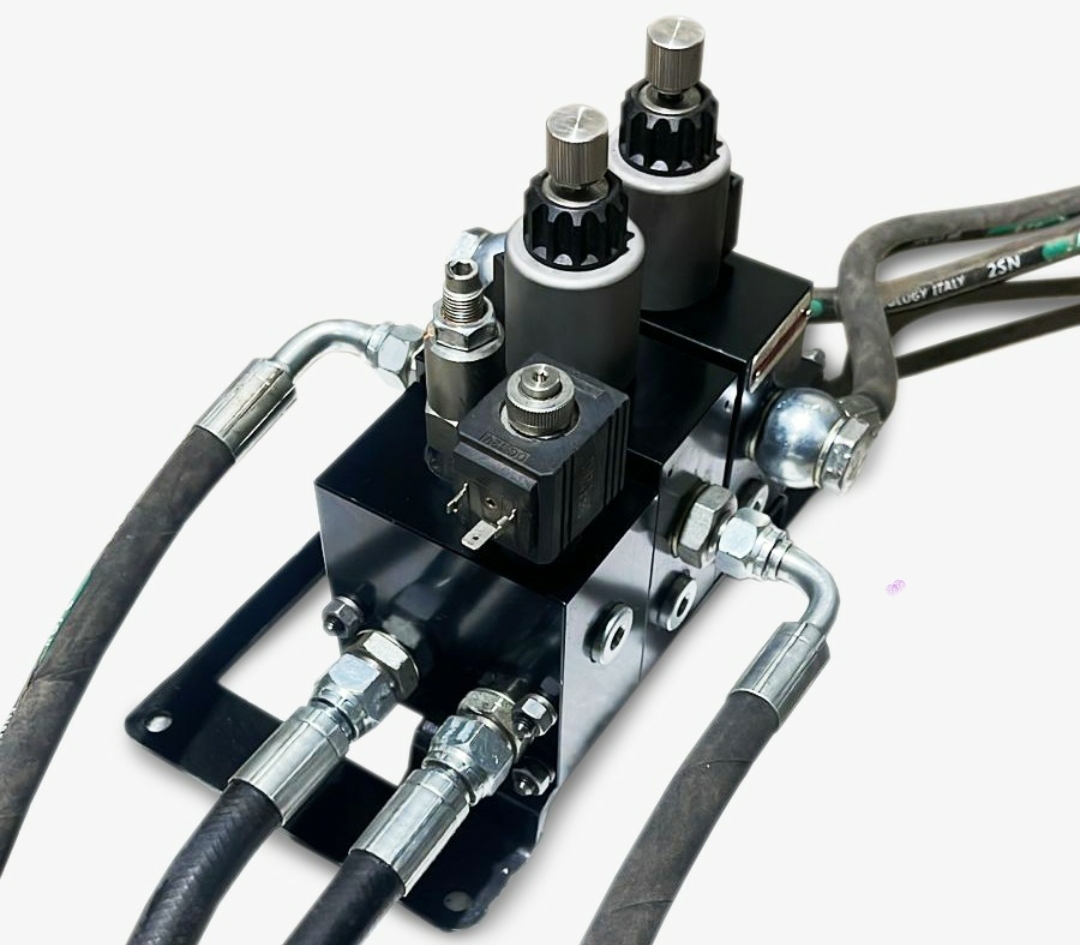

- The hydraulic drive system of the dispensers with software control is designed for the operation of the seeding complex according to task maps, with the possibility of differentiated application of seed material and granular fertilizers, as well as control of the seeding rate through the monitor of the navigation complex.

- The hydraulic drive system of the dispensers with software control ensures the rotation of the seeding rollers of the metering mechanisms in the entire range of speeds and seeding rates of the seeding complex, is an optional replacement for the mechanical drive of the dispensers with a variator, while significantly simplifying the calibration of the dispensers and the setting (change) of the seeding rate of the seed material and granular fertilizers from 2.5 to 400 kg.

- The system is equipped with an individual two-section hydraulic distributor with proportional control of each hydraulic motor, changing the rotation frequency of the seeding roller depending on the speed of the seeding complex and the rate of application of the material.

- Additional requirements for the hydraulic system:

- Availability of a free flow section of the tractor hydraulic distributor with the ability to adjust the flow of hydraulic fluid. Hydraulic flow – from 60 l/min at 185 bar

Speed is measured by two independent systems: by GPS signal and by speed sensor. If GPS signal is lost or unstable, the system switches to the signal from the wheel speed sensor.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- датчики бункера (блок запуска муфты, блок сбора данных, датчики вращения вала дозатора, вентилятора, датчик наполнения бункера, датчик давления бункера) - датчики высевающей части (датчик забивания семяпроводов, датчик положения культиватора). |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.

Посевные комплексы серии S (транспортная ширина 3 метра) для внесения жидких удобрений агрегатируются с автоматической системой внесения жидких удобрений "Спутник-4000" или "Спутник-6000"

Высевающая часть посевного комплекса дополнительно оснащается:

- системой трубопроводов, форсунок и питателей

|

|

|

|

|

|

9,6 |

12 |

|

|

|

|

|

|

20 |

20 |

|

|

9,9 |

11,85 |

|

|

15 |

15 |

|

|

66 |

78 |

|

|

6,5 |

6,5 |

|

|

3-8 4-6 |

3-8 4-6 |

|

|

2,5-400 |

2,5-400 |

|

|

|

|

|

|

|

|

|

|

6900 |

7800 |

|

|

13900 |

14800 |

|

|

10000 |

12500 |

|

|

3800 |

3800 |

|

|

|

|

|

|

6125 |

7025 |

|

|

13125 |

14025 |

|

|

3000 |

3000 |

|

|

3835 |

3835 |

|

|

300 |

300 |

|

|

5500 |

6700 |

|

|

9500 |

10700 |

|

|

3,6 / 2,4 |

3,6 / 2,4 |

|

|

7 |

7 |

| 200-270 | 300-350 |