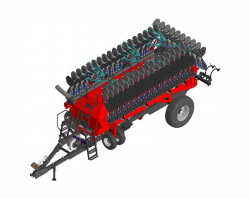

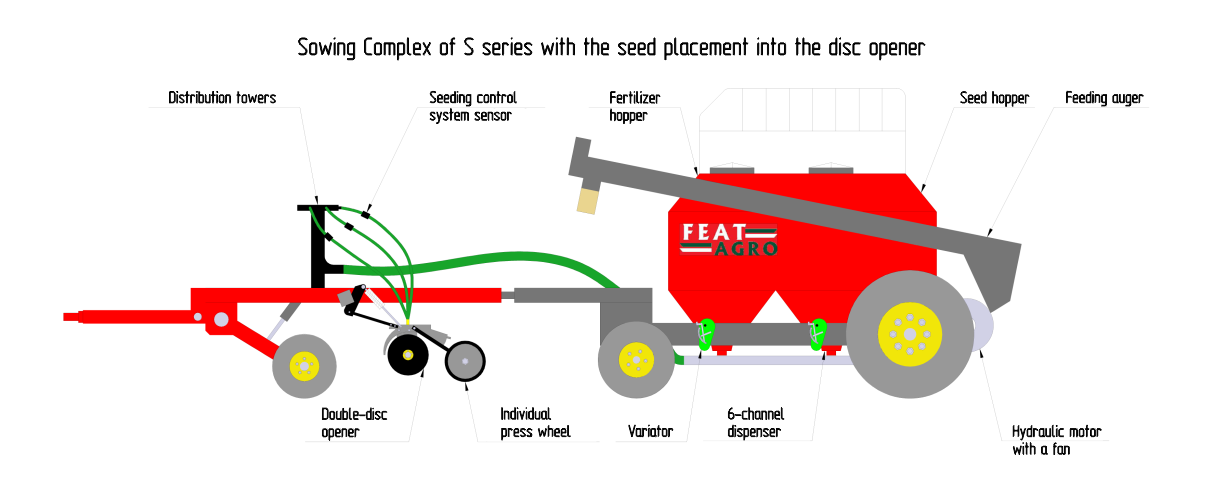

Victory (SZ) Sowing Complexes of FEAT series with seed placement into the disc coulter

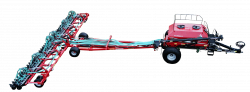

- The large working width when aggregating with the tractors of a small drawbar category and, as a result, the increased productivity of the seeding machine;

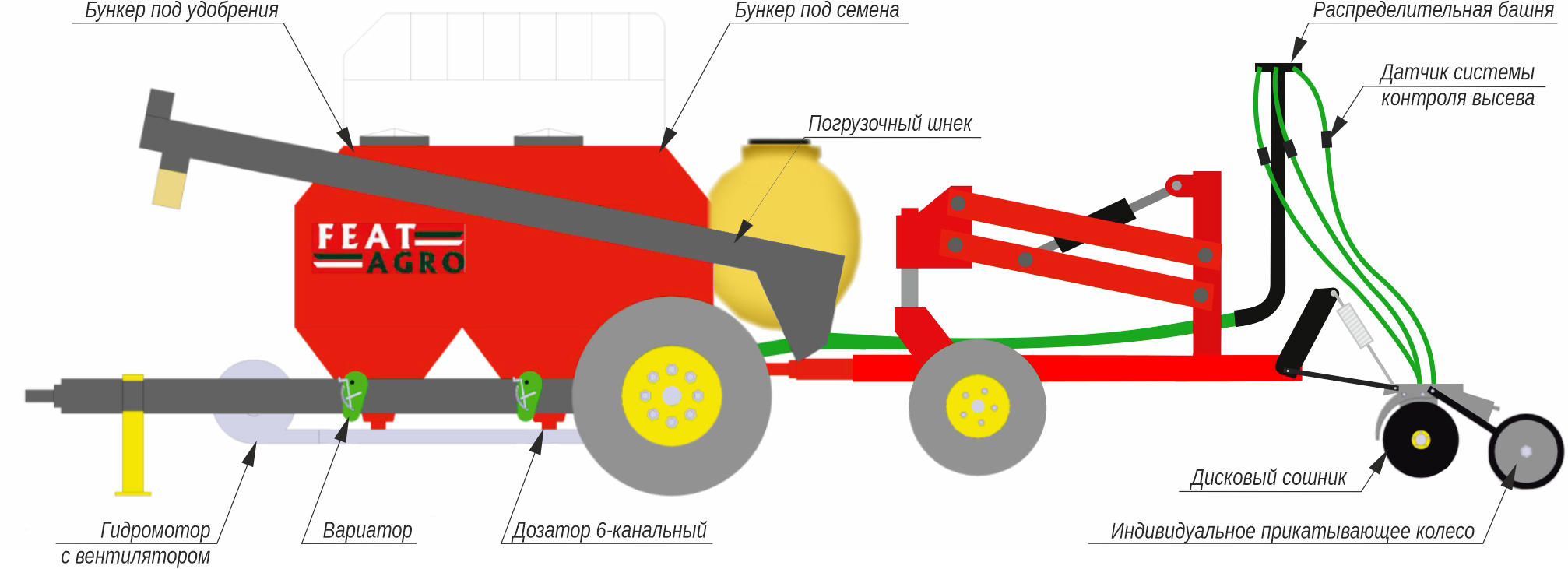

- The six-channel distribution of the seed flow – dosing accuracy in the whole coulter group and minimum damages to the seed materials;

- Possible simultaneous application of seeds and mineral fertilizers;

- Thanks to a complex of manual and hydraulic settings, high accuracy of the seeding depth is provided;

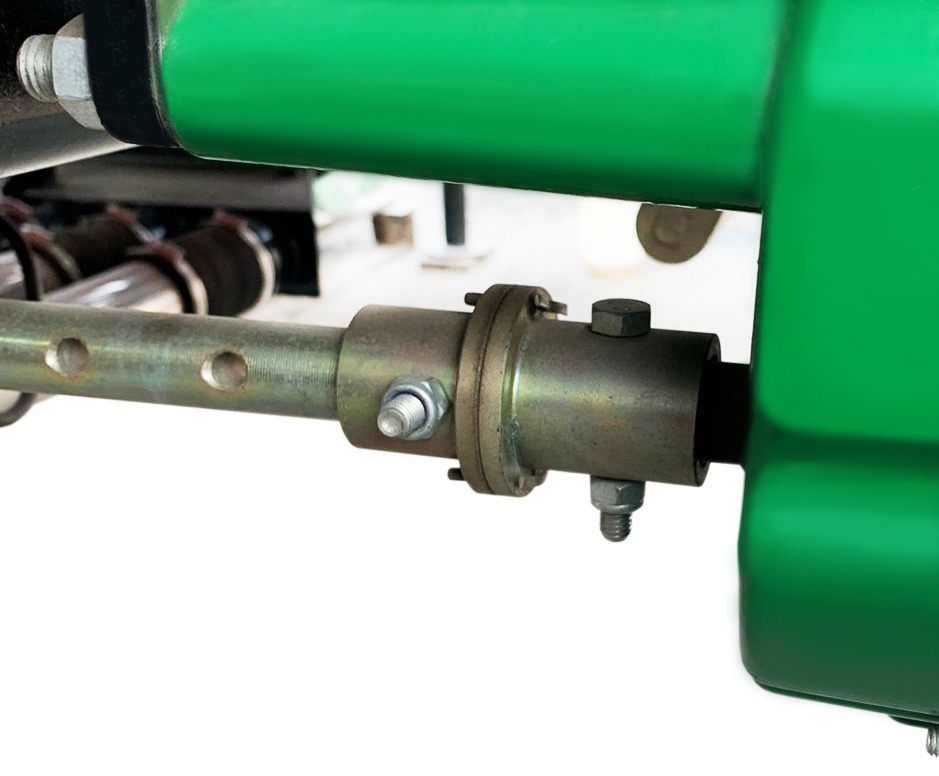

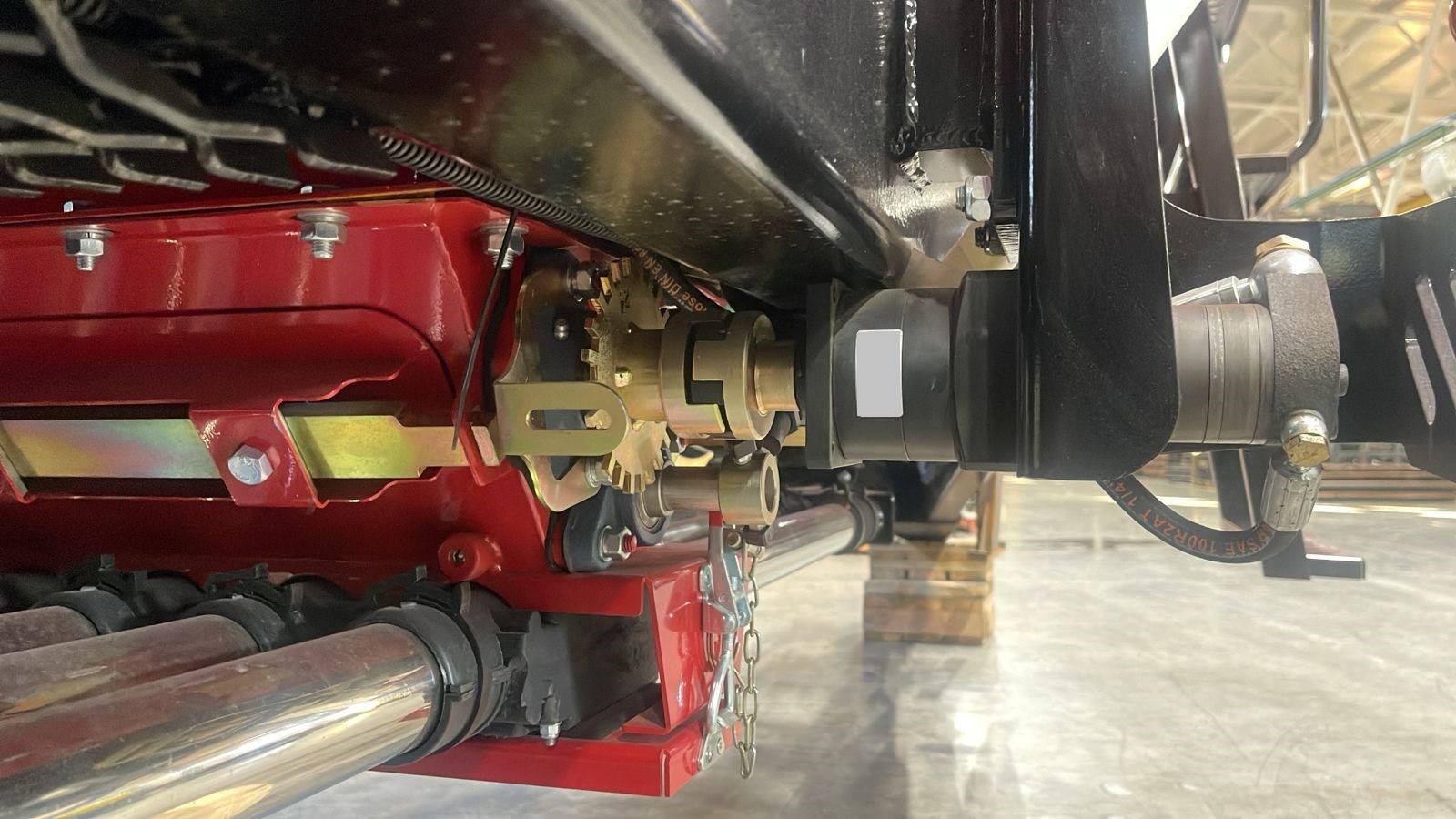

- The structure of the variator together with a dispenser installed on the hopper ensures an easy and highly-precise setting of the seed sowing from 2,5 kg/ha to 400 kg/ha;

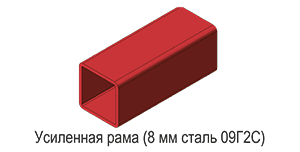

- High lifespan of the frame – it is made of thick-walled structural-grade steel 09G2S, all bearing units are additionally reinforced;

- Agricultural bearings with a special triple sealing FKL (Slovenia) are installed at all assembly units operating under extreme conditions;

-

Disc coulters with the guaranteed operating time for a bearing group of at least 200 hectares per coulter;

-

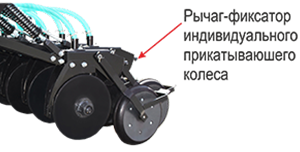

Semi-pneumatic rollers with an separate scraper - a guarantee of self-cleaning on the soil with high moisture;

-

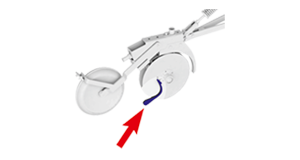

A wiper on the disc coulter housing prevents the disc coulter from clogging with soil and plant residues;

-

The individual mechanical spring adjustment of disc coulters in combination with the adjustment of hydraulic cylinders allows creating the pressure on the disc coulter up to 84 kg - provides a stable sowing depth in different soil types with different agro-climatic conditions;

-

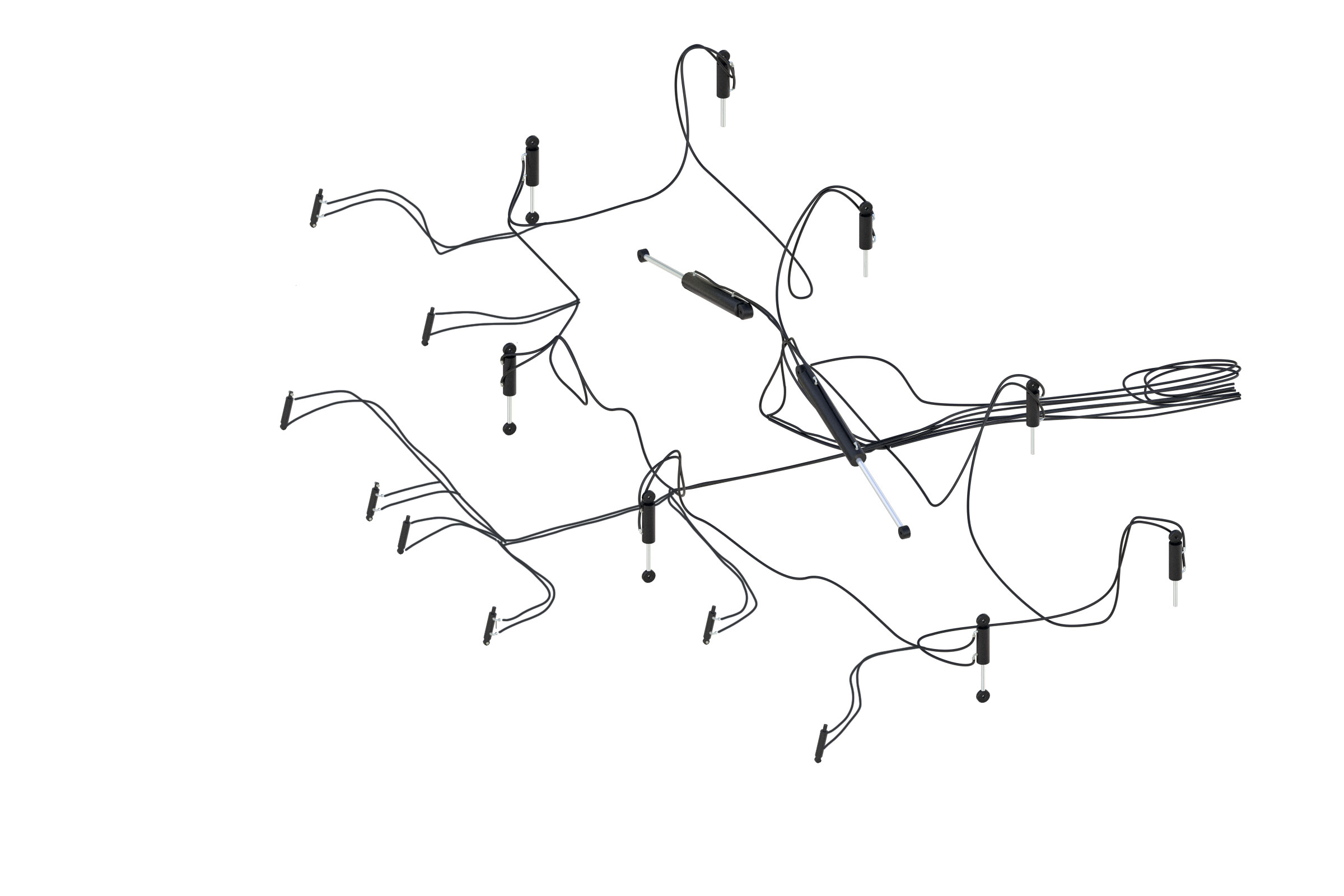

There is a pneumatic seeding control system installed – DPP sensors (sensor of passage of the seed material and granulated fertilizers), intended to collect information about the passage of seeds and fertilizers and to transmit this information to the monitor. The sensors are installed from the outside of each seed drill tube, both for the seeds and fertilizers. In case of clogging of the seed drill tube, the DPP sensor signals the clogging, the number of the clogged seed drill tube lights up on the monitor and an audio signal sounds;

-

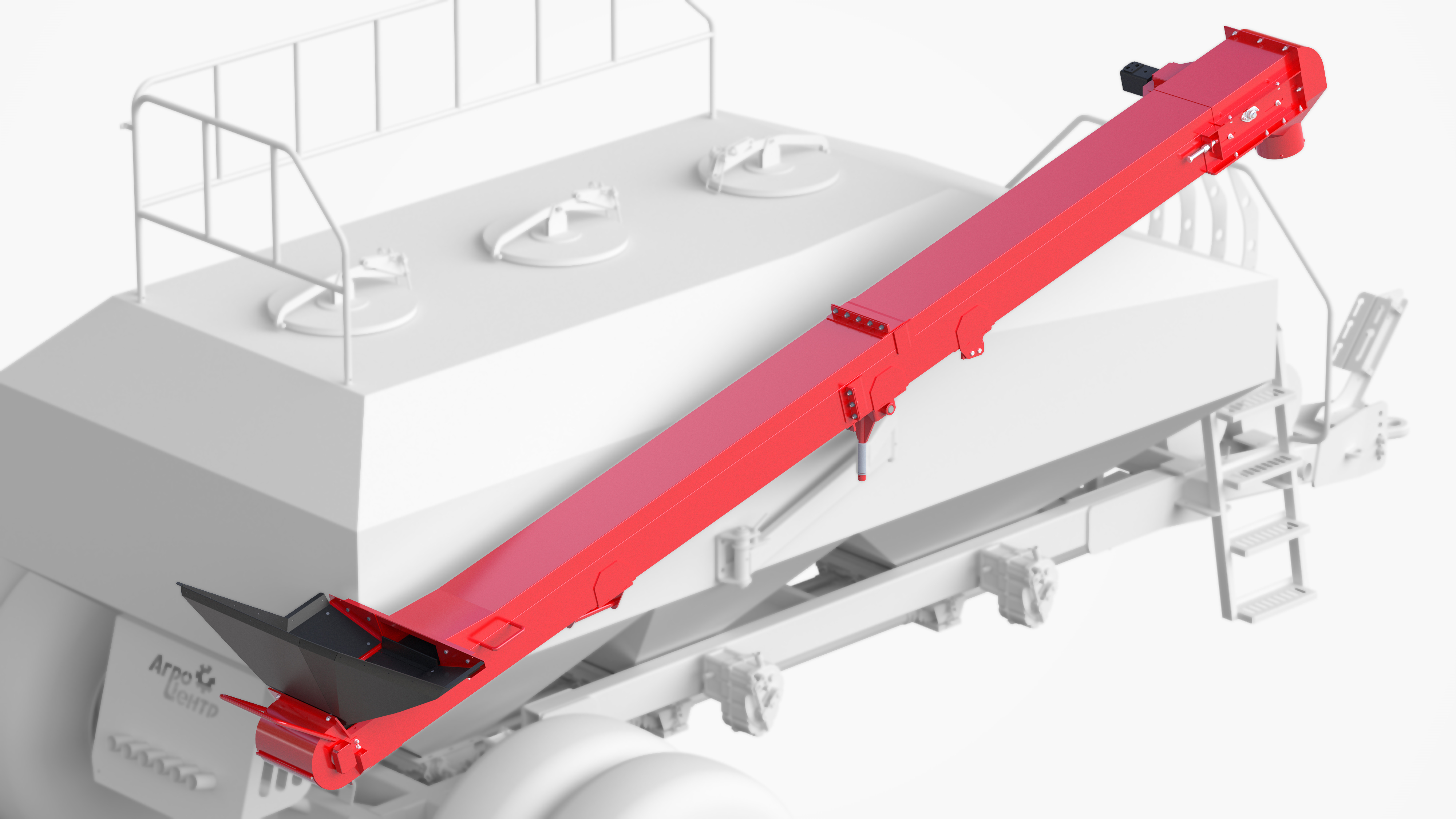

Two location variants of the hoppers which are easily detachable from the frame – posterior-mounted or anterior-mounted one with the volume of 6.8 m3 (factory package) or with the volume of 10,0 m3 (optionally).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- датчики бункера (блок запуска муфты, блок сбора данных, датчики вращения вала дозатора, вентилятора, датчик наполнения бункера, датчик давления бункера) - датчики высевающей части (датчик забивания семяпроводов, датчик положения культиватора). |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

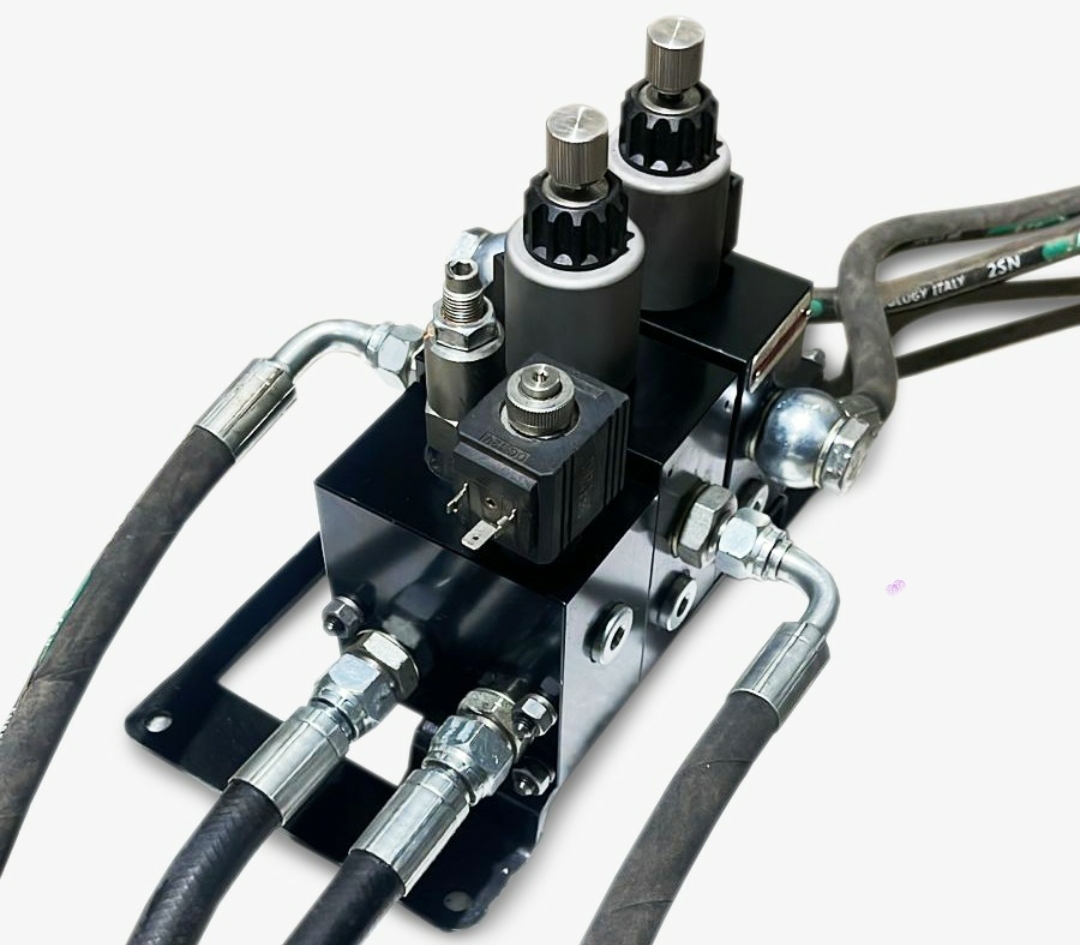

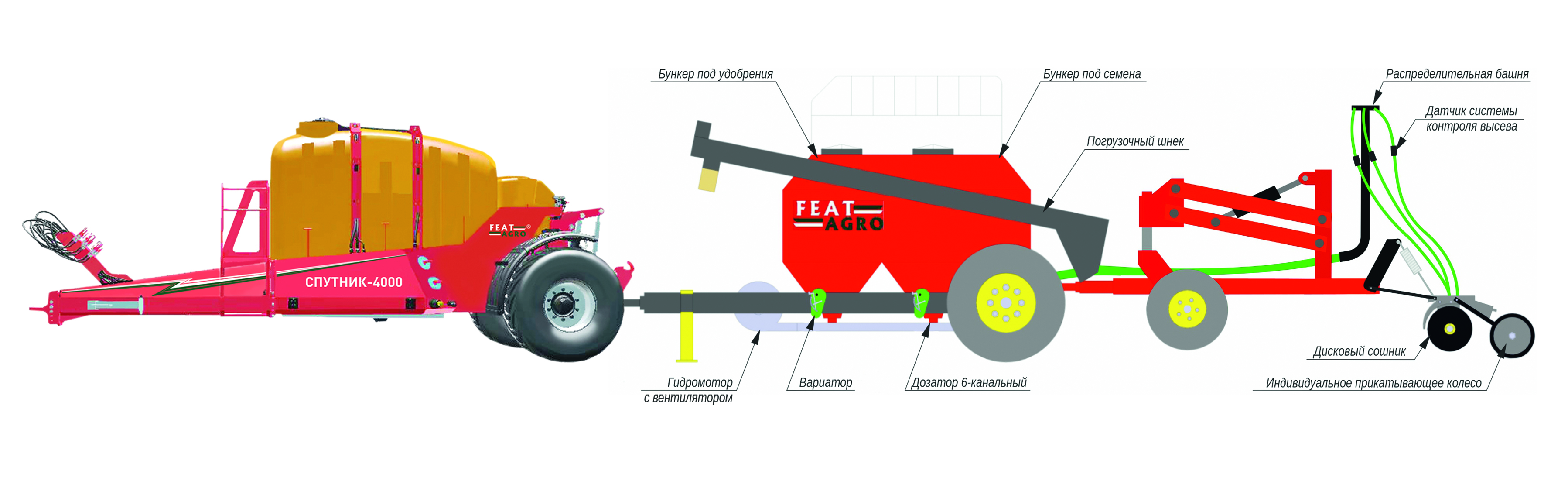

Внесение жидких удобрений одновременно с посевом сельскохозяйственных культур посевными комплексами серии S может осуществляться двумя способами:

1. Бункер посевного комплекса опционально оснащается:

- ёмкостью объёмом 2 м.куб. под жидкие удобрения (типа КАС);

- приводом жидкостной помпы от героторного гидромотора;

- блоком программного управления выливом жидких удобрений

Высевающая часть посевного комплекса дополнительно оснащается:

- системой трубопроводов, форсунок и питателей.

2. Посевные комплексы серии S для внесения жидких удобрений агрегатируются с автоматической системой внесения жидких удобрений "Спутник-4000" или "Спутник-6000"

Высевающая часть посевного комплекса дополнительно оснащается:

- системой трубопроводов, форсунок и питателей

|

Parameter name |

S-9600 |

S-12000 |

||

|

Operating width, m |

9,6 |

12 |

||

|

Productivity per 1 hour of basic time (at the speed of 12 km/h) ha, not less than |

9,6 |

12 |

||

|

Number of disc openers, pcs. |

66/54 |

78/72 |

||

|

Row spacing, cm |

15/17,2 |

|||

|

Seed placement depth, cm |

3-8 |

|||

|

Seed application rate, kg/ha |

2,5-400 |

|||

|

Loading volume of seeds 60%/fertilizers 40% |

6,8 m³, 10 m³ |

|||

|

Transport speed, km/h, not more than |

20 |

|||

|

Seeder dimensions in the working position, mm: |

length |

12500 |

12500 |

|

|

width |

10000 |

12500 |

||

|

height |

3800 |

3800 |

||

|

Seeder dimensions in the transport position, mm: |

length |

12500 |

12500 |

|

|

width |

4900 |

6200 |

||

|

height |

3800 |

3800 |

||

|

Seeder weight without a seed hopper, kg |

5200 |

6500 |

||

|

Seed hopper weight (6,8 m3), kg |

4500 |

|||

|

Service life, years |

7 |

|||

|

Number of operating staff, persons |

1 |

|||

.png)